Since our founding in 1996, our assembly and fastening solutions have been instrumental in resolving our customers' manufacturing challenges.

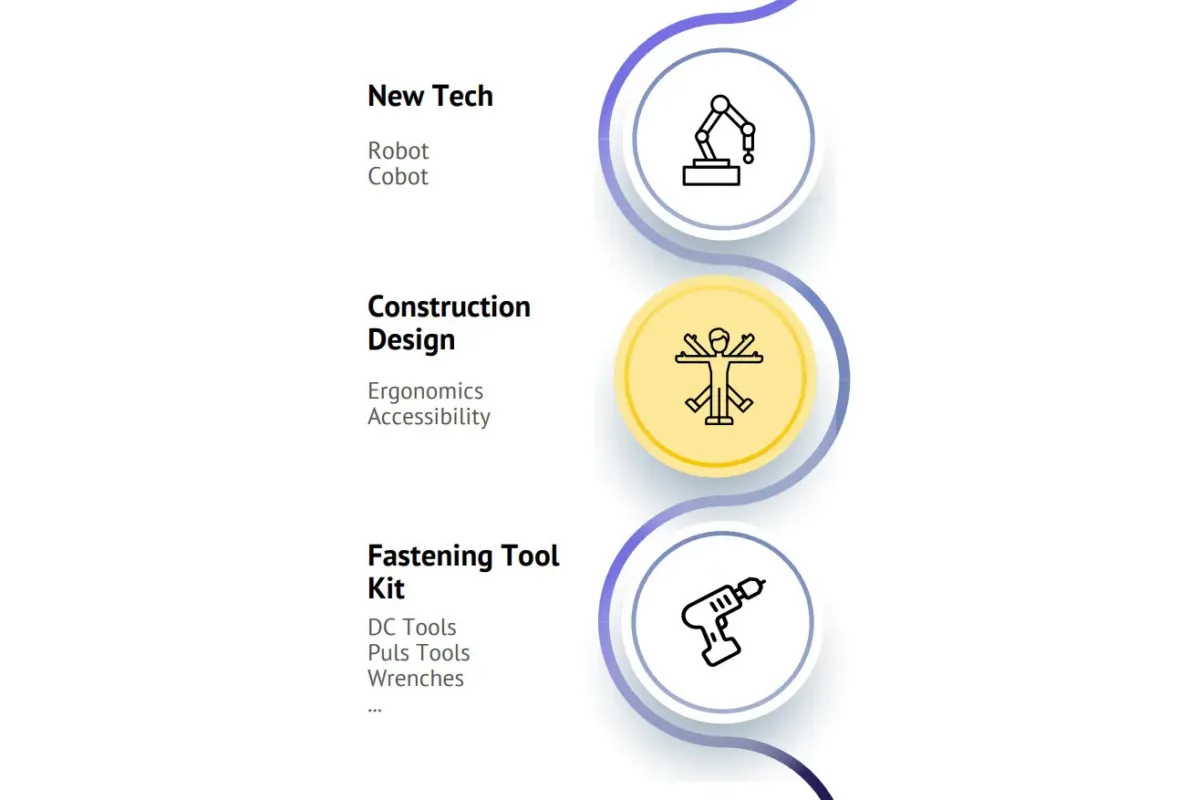

Cobot is the hardware version of Augmented Intelligence and has the potential to revolutionize production environments. Dirty, unsafe, repetitive tasks can be performed by a cobot so that your workforce can concentrate on other tasks. Ansomat is continuously evaluating new technologies to support our clients in increasing operations productivity and efficiency through digital initiatives.

Operator ergonomics and safety are of extreme importance in production environments. To avoid muscular disorders caused by frequent repetitive movements, we offer tailor-made constructions with built-in safety mechanisms.

Besides, many manufacturers still need to cope with "blind" spots in their assembly processes. For Ansomat no inaccessibility issue is an obstacle. We are renown for delivering mobile and fixed construction to encounter any accessibity issues.

Thanks to our long experience in the field, we advise our clients on the most suitable fastening tools for their projects. Our portfolio consists of world-class accurate and durable products. Ranging from basic to intelligent battery tools, torque wrenches, corded DC tools, multispindles and many more.

A Toolkit for Any fastening project

Our ergonomic solutions are the perfect combination of proven durability and engineering perfection. They allow full-range of motion required to complete any task more efficiently and safe. Based on your requirements, we can adjust these standardized arms. In this way workers can use high torque tools more accuratelynand decrease the chances of injury due to strain.

Not all components are easily accessible for tightening purposes. Examples include swing bearing of an excavator. The bolts to be tightened have difficult access. Our accessibility solutions prove to be very effective in reaching the most difficult blind spots. Solutions can be fixed or mobile, with or without a smart computer for traceability.

Car and heavy machinery are becoming smarter every day. That is why Ansomat is always looking into new technologies which supports humans in making their work easier, more accurate and less repetitive.

Robots are designed to do work in place of employees. They are used to fully automate an assembly process entirely without the help of humans on the shopfloor. In turn employees time is freed up for more meaningful and less repetitive tasks.

Cobots are designed to work alongside humans. They can assist operators with work that might be too dangerous or tedious to accomplish on their own. This way manufacturers create safer, more efficient workplaces without eliminating jobs.

Step into the future of smart guided manufacturing!